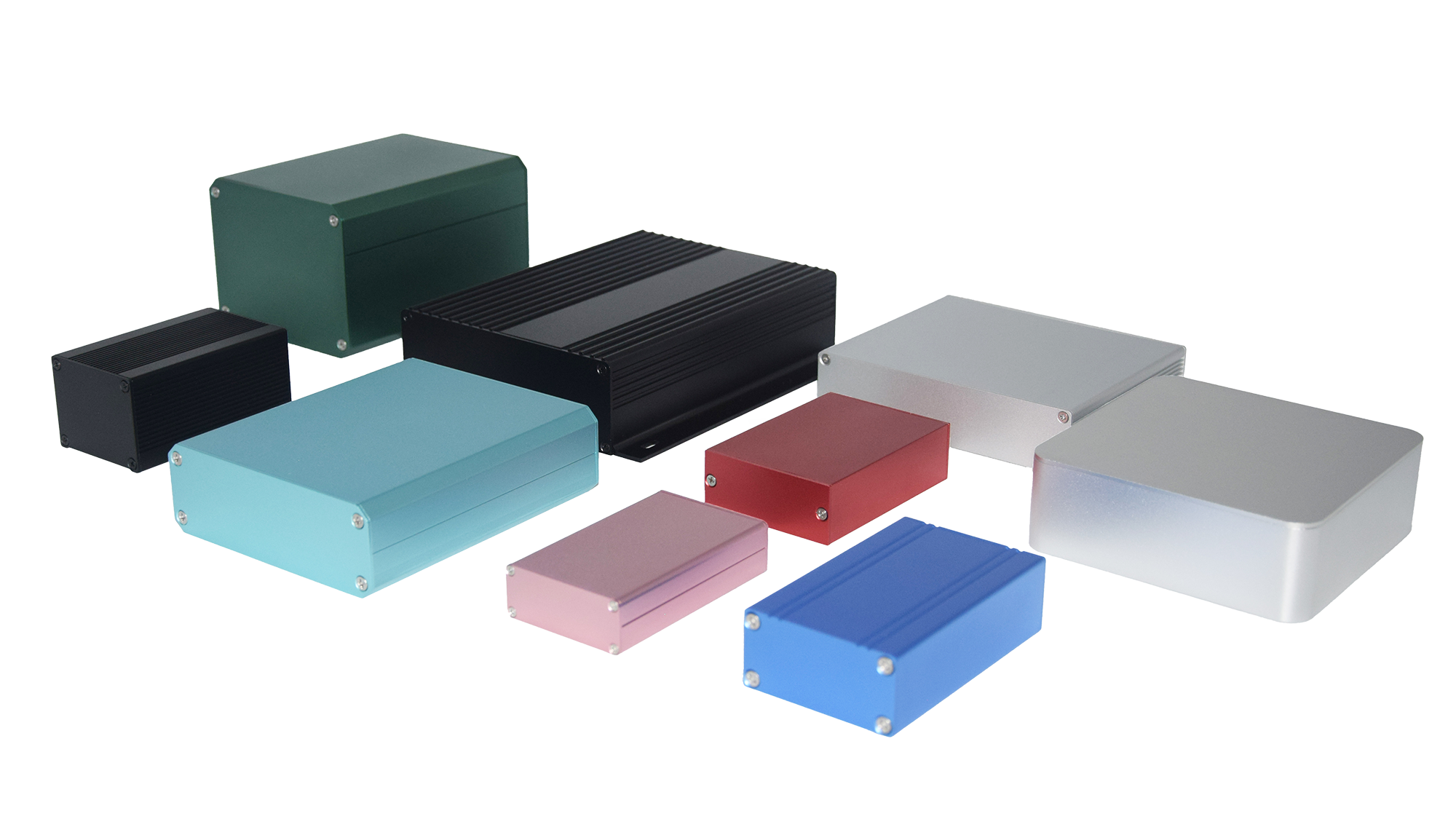

Aluminum Extrusion Enclosures

Function-driven with a balance of aesthetics and durability — it is precisely because aluminum extrusion enclosures are lightweight, highly thermally conductive, and corrosion-resistant that they are favored by equipment manufacturers.

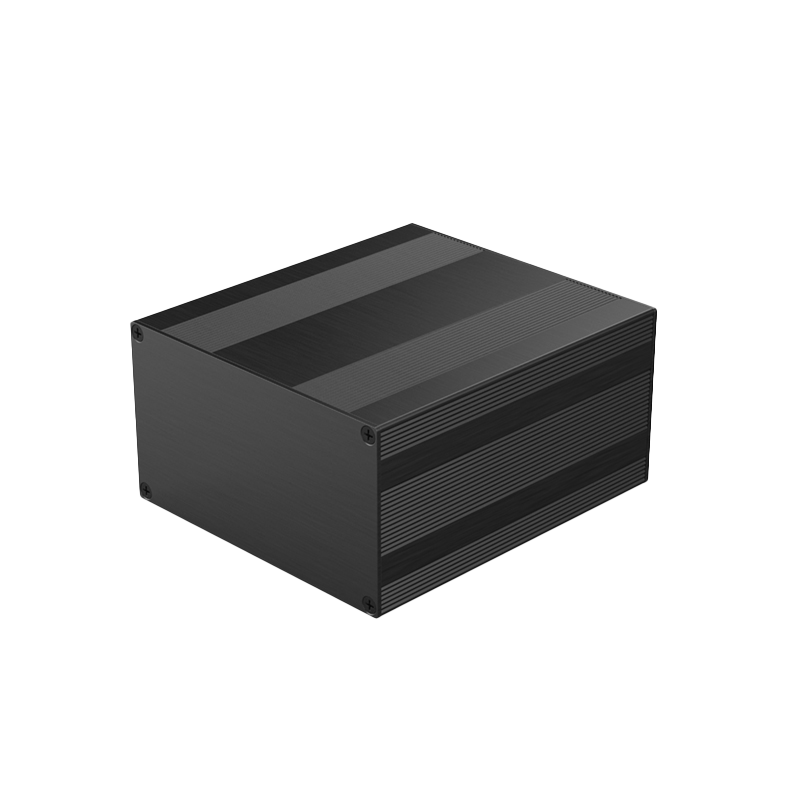

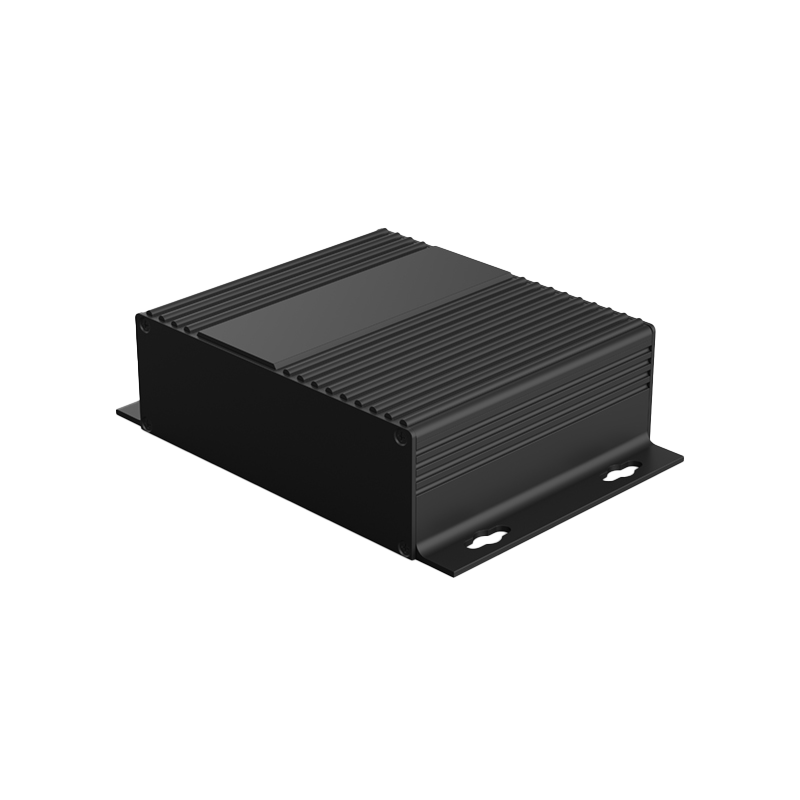

High-Precision Industrial Enclosure

- 6063-T5 high-strength aluminum alloy

- Tight tolerance (±0.1mm) for seamless assembly

- Multi-slot design for standard accessories

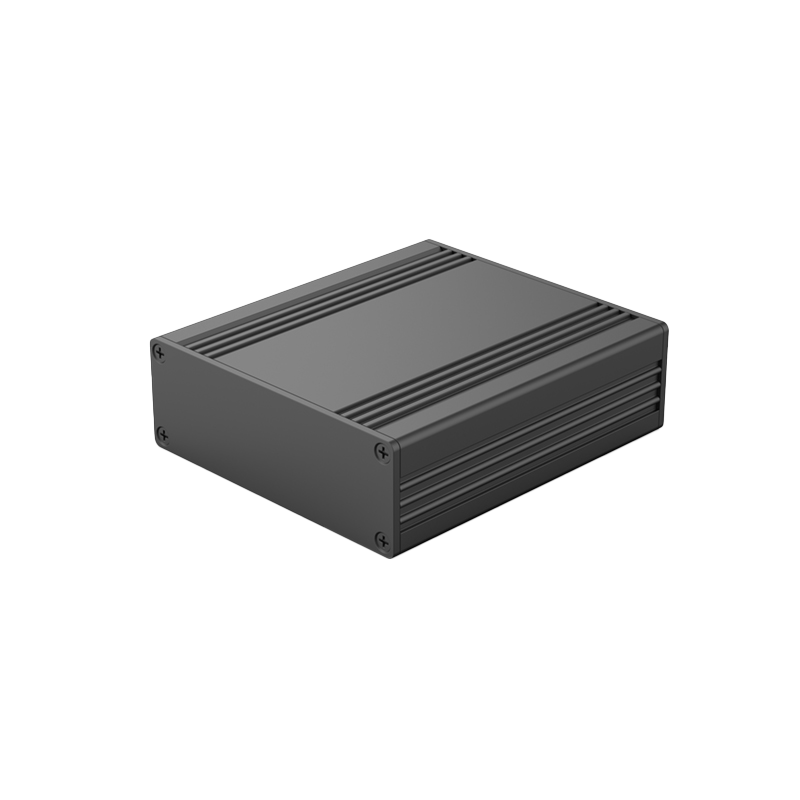

Ultra-Thin & Lightweight Enclosure

- 1.2mm thin-wall construction

- Anodized finish (silver/black/gold/gray)

- Fingerprint-resistant coating

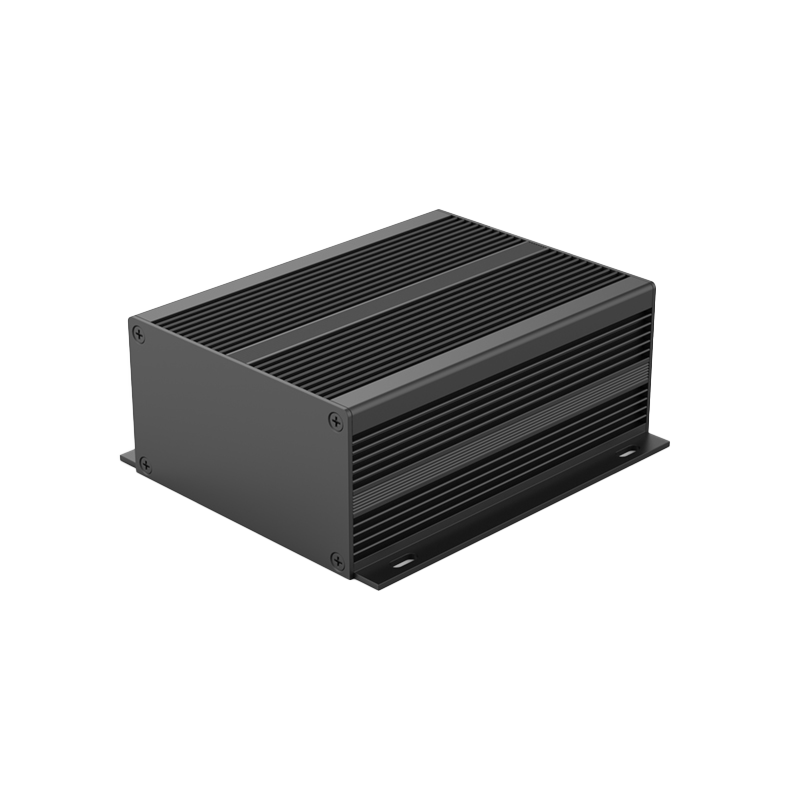

High Thermal Dissipation Enclosure

- Integrated cooling fins for efficient heat transfer

- 6061 aluminum alloy (160W/mK thermal conductivity)

- Sandblasted surface for enhanced heat dispersion

Corrosion-Resistant Outdoor Enclosure

- AlMg4.5Mn alloy, resistant to salt spray/rust

- IP65 rating (dustproof & waterproof)

- UV-resistant electrophoretic coating

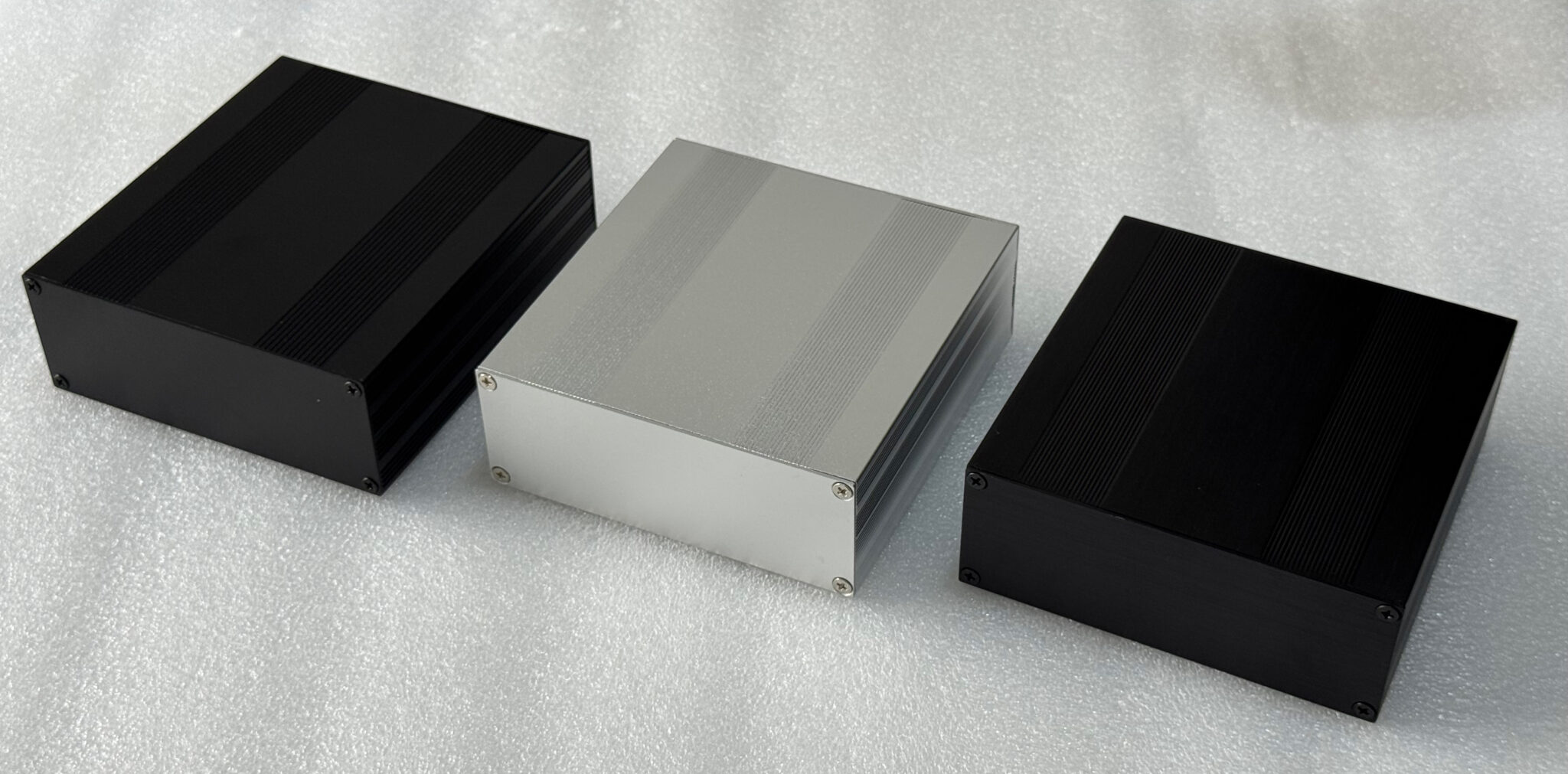

Aluminum Profile Enclosure Example

One Piece Enclosure

One Piece Enclosure with Flange

Split Enclosure

Split Enclosure with Flange

Our enclosures are designed for adaptability and durability:

- One-Piece (Earless/Eared): Streamlined or easy-mount designs for compact or industrial use.

- Split-Type (Earless/Eared): Modular flexibility for maintenance-friendly applications.

- Custom Options: Sliding rails, hinged doors, or sealed IP-rated variants available.

Ideal for electronics, automation, energy, and automotive sectors—combining lightweight strength, heat dissipation, and corrosion resistance.

Engineered to fit. Built to last.

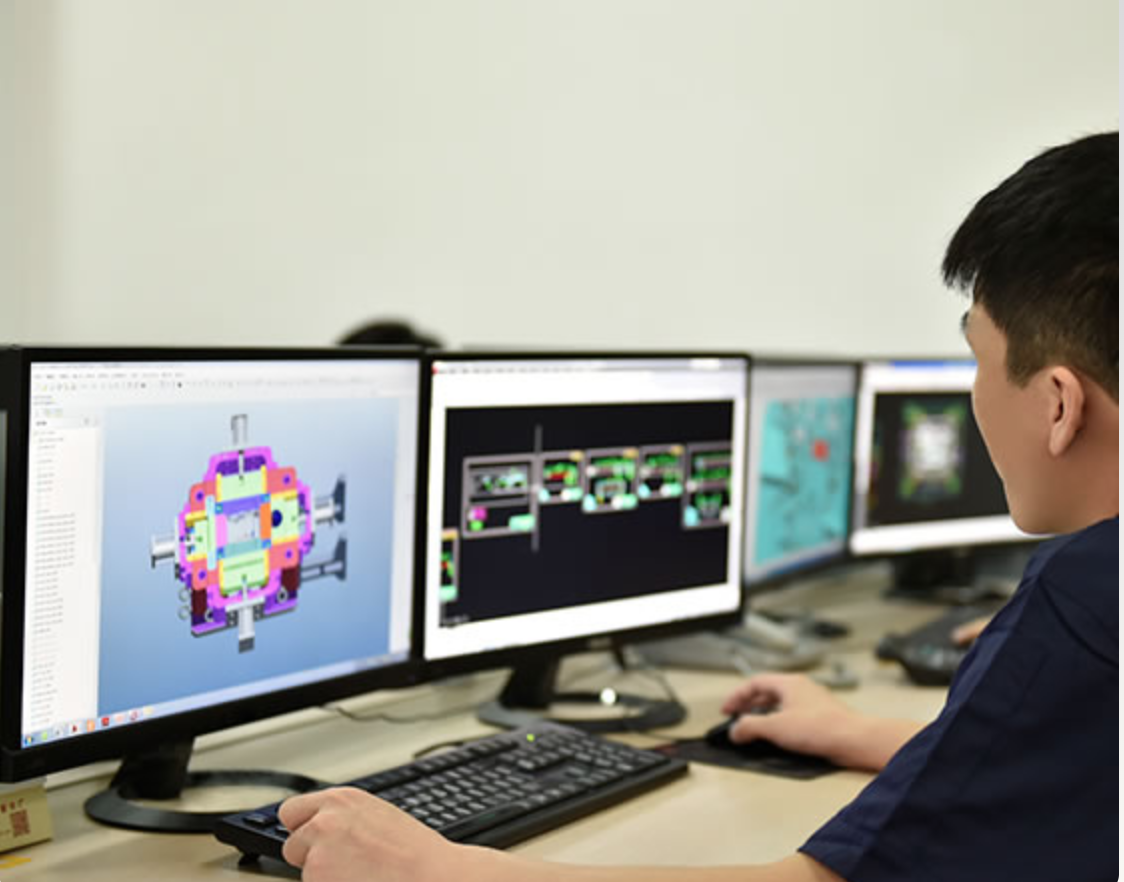

Aluminum Profile Enclosure Customization Process

Requirement Confirmation

Application scenarios (industrial/consumer electronics/automotive etc.)

Core requirements (dimensions, IP rating, thermal management, load-bearing capacity)

Budget and delivery timeline

Design & Development

Provide 2D drawings/3D models (customer-provided or our design)

Structural optimization (wall thickness, mounting points, cooling solutions)

Surface treatment selection (anodizing, sandblasting, painting etc.)

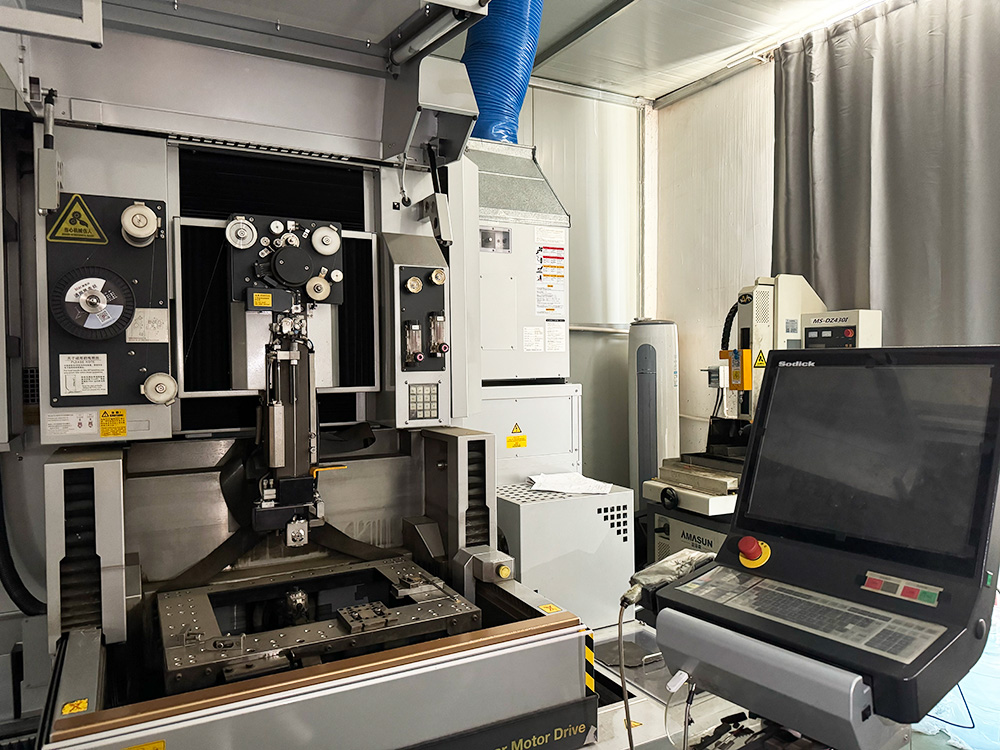

Mold Fabrication

Extrusion mold development (5-15 days depending on complexity)

Mold testing and sample adjustment

Sample Prototyping

Provide 1-3 samples for functional/structural testing

Support dimensional, assembly and environmental validation

Mass Production

Profile extrusion → CNC machining → Surface treatment → Quality inspection

Full-process progress tracking and key milestone approvals

Which material or process is the perfect match?

We will be happy to advise you.

XISENC

High-pressure die casting, semi-solid die casting, aluminum extrusion, sheet metal fabrication—from XI Mach you get everything from a single source. Individually tailored to your enclosures parts production.

+86 156 2049 0719

info@xisenc.com

300400, High-Tech Zone Beichen Science and Technology Park, Beichen District, Tianjin, China